Steel Printing Services

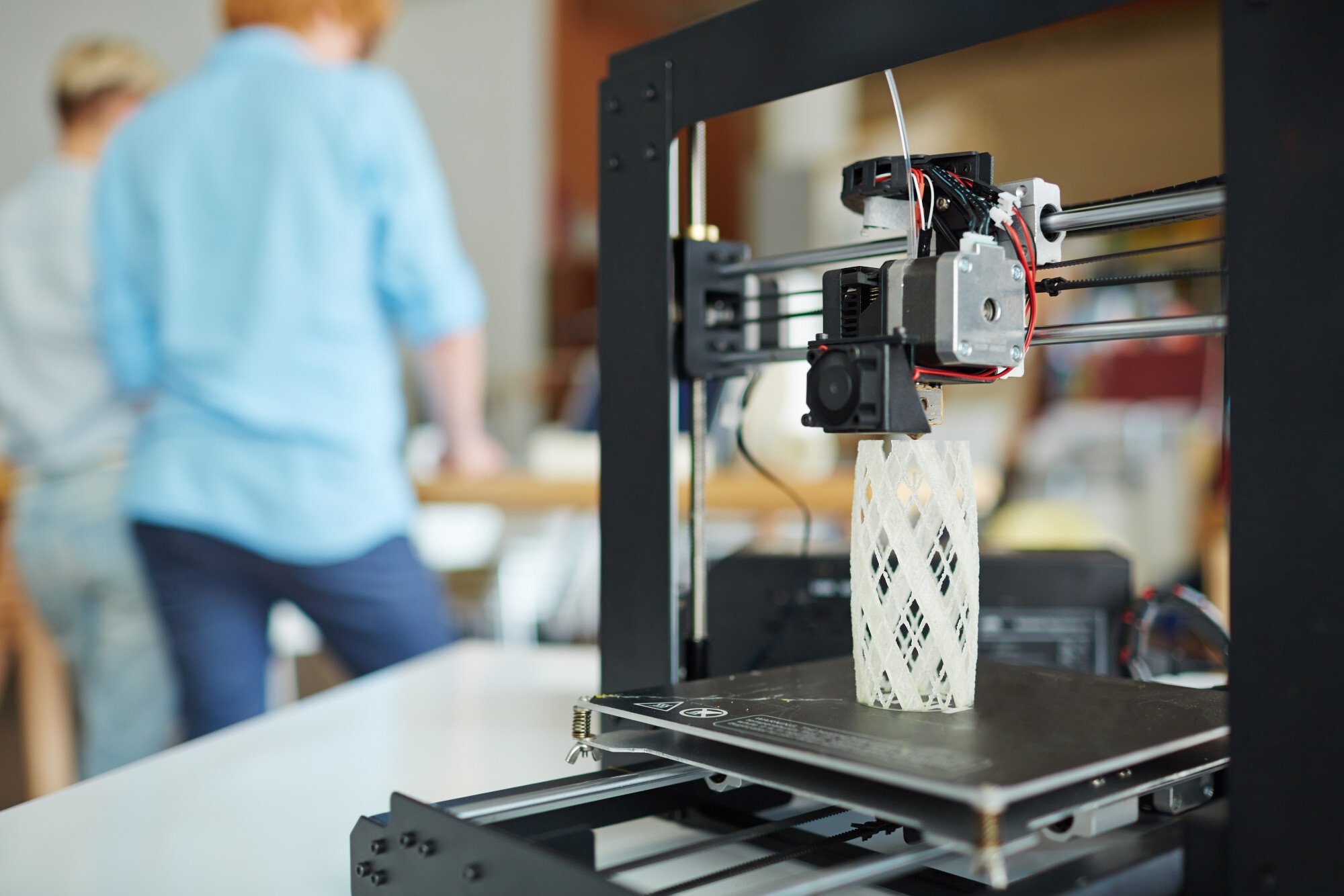

Steel 3d printing is likewise known as zinc steel printing or zinc metallic printing. It is a kind of metal printing procedure that utilizes zinc powder in the form of sheet steel. This is a flexible printing procedure that can be utilized both for level and also thin sheets. The printing process does not incorporate any kind of clear filaments. Rather, it relies upon a fine, high-carbon steel powder inks. The ink is placed on the wanted area of the metal and afterwards the powder is made use of to transfer the colors on the steel making use of an electrically warmed drum.

The resulting printout is after that cooled down in an autoclave maker and laminated flooring with premium material. This approach of metalworking offers various advantages, such as high durability, uniformity, as well as broadband. The printing powder utilized by 3D printer systems can either be any kind of type of powdered powder, as it will certainly be utilized for thin, ultra-fine layers just. The resulting layer of the end product is after that cured using extremely powerful, above tanning lights. There are several applications of steel 3d printed components in the aerospace as well as protection market. For example, they are widely used to create the wings of fighter jets, which are made from composite materials.

An additional usual use is in creating component components for projectiles and also other missiles, which are strong pieces of steel. Components made out of metallic additive manufacture technology (MAD) are commonly made use of to develop parts or components for room vehicles. There are a couple of concerns, though, with utilizing metal powder in printing. One issue is with melt-through, which happens when the ink in the inks are too thick to completely thaw through the thickest item of filament during the printing procedure. When this occurs, the outcome is the photo on the other side does not totally match that of the top layer. This is called a 'crunchy' impact. Depending on the top quality of the printer and the overall quality of the photo, occasionally this may not be a problem, yet when the coating is thin, the effect is noticeable. Get more detailed information on this page about why you should consider using 3D printing and additive manufacturing.

An additional concern with making use of metal powder in the printing process is with bpe (bsop) printing, which is the procedure of feeding continuous roll after roll of solid material through a filter to draw out the little elements of the solid material. For example, this would be finished with brass, which is mainly utilized in motor components due to its resilience and also small cost. Occasionally, the bpe or spool will not pass through the sieve and the small components will fall out, resulting in a 'damp feed' failing. Metal pollutants in solid elements can trigger this 'completely dry feed' failing, which can cause components published with not enough layer to avoid dry feeding. The good news is that many metal powders have been established to combat these troubles. Some of these techniques consist of post-processing that enables you to clean up your job if the contaminants are discovered prior to the last layer is printed, and also different kinds of securing that prevents the metal fragments from restraining picture circulation or changing the shade of the last photo.

These techniques can be integrated to offer more effective lead to printing, as well as guarantee that your prints are resilient as well as will not deal with problems connected with utilizing metal powders. Generally, it appears as though using steel powders in commercial components printing has actually been restricted till just recently, however as brand-new modern technologies emerge to help deal with these issues, this practice can come to be more commonplace. To get detailed information related to this topic, click at : https://en.wikipedia.org/wiki/3D_printing_processes.